Processing with allmineral technology

A series of demanding steps must be completed to ensure the correct processing of ores and perfect sorting into various qualities. In general, the aim is to enrich the raw ore content to meet the level required by the market. allmineral jigs and up flow sorters have proven themselves ideal for this purpose, as their high throughputs ensure the necessary product quality with low specific costs.

We are your expert partner for handling ores:

- Seamless sorting of challenging materials featuring a large number of fractions close to the separation density

- Outstanding user-friendliness and easy configuration of all machines – even during operation

- Highly robust plants with excellent variability

HAZEMAG allmineral Australia local manufacturing and refurbishment services of allmineral classifiers for the Australian Iron Ore market.

Earlier this year HAZEMAG allmineral Australia manufactured 2 x allflux® classifiers locally in Perth, Western Australia for one of its key customers in the Pilbara region. The manufacturing and factory assembly testing was done in Perth, completed, and transported under heavy haulage road escort to the Pilbara region of Western Australia.

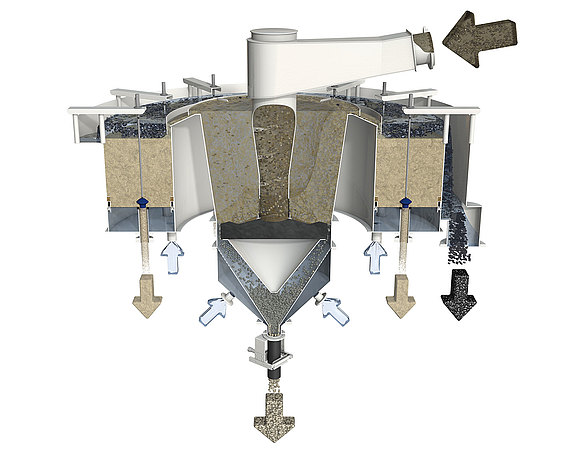

The supplied allmineral’s allflux® classifier is a unit designed to treat iron ore particles in two classification stages that upgrade the valuable mineral by size and density and desliming in one step. Sorting, classification and cleaning all performed in a single unit. Consistent material quality via automatic process control and low energy requirement and low wear.

In allmineral we engage with our customers to understand their plant requirements and we strive for economical production using highly effective sorting in conjunction with classification and a lofty throughput.

The allflux® has also been introduced in the sand and concrete industry bring sustainability in processing with allflux®

Thanks to the new generation of control software and a whole host of additional improvements, the allflux® fluidised bed sorter not only reliably separates organic impurities but also produces and mixes high-precision sand fraction classes. This means that compact plants requiring low investment and operating costs can generate high-quality sands according to a recipe, even when using partial flows in existing facilities.

Since the market launch of the allflux® fluidised bed procedure in the sand and concrete industry, this technology has been successfully used in numerous other application areas. Fine coal recovery from tailings ponds, ore and mineral sand processing, and the recovery of glass and sand from household waste are just some of the many applications in which the allflux® fluidised bed procedure has been deployed.

The use of the fluidised bed procedure reduces operating costs as several process steps are combined in a single machine. This helps save on cyclones, classifiers, sorters, thickeners and hundreds of coils, for example. The allflux® is an energy efficiency solution thanks to material feed-in via free flow or low level of advance pressure.

Technical Specification

- Processing of grain sizes up to 4 mm

- Generates autogenous heavy slurry for the separation of light materials

- Various build sizes with diameters of up to 7 m

- Can handle up to 2,000 m3/h of feed material and 800 t/h of solids in one unit

- Hydraulically controlled discharge devices

- 3-stage process without moving parts

Benefits of this technology

- The allflux® brings together a number of different process steps in a single unit

- Generates products in three high-precision classes

- Produces special sands through mixing, both online and offline

- Solids content in feed material can be adjusted within a broad range

- Energy efficiency thanks to material feed-in via free flow or low level of advance pressure

Refurbishment of classifier services by HAZEMAG allmineral Australia

In our effort to support our customers growing market needs, optimise equipment life, reduce capital cost where possible, we are working closely with our customer on their installed machines offering onsite audits and refurbishment services.

The refurbishment services have the potential to increase the life of the machine substantially, with yearly machine audits done, we can timeline when certain sections of the machine need to be refurbished and plan accordingly coordinating with site maintenance shutdown timelines.

We are working with our customer to understand their parts and service requirements, our warehouse in Canning Vale is being upgraded to fully stock all essential parts to service our customer base. We are working with our customers to optimise our service parts offering by looking at kit set up supply specific to individual machine component services, this enables efficiency in service operations for our customers.

HAZEMAG allmineral Australia is here to listen to your needs and find ways to provide solutions that meet your needs, let us come together and work together to find the optimal, resource and time saving solution for your business. Your success is our success.

Contact us:

HAZEMAG allmineral Australia Pty. Ltd.

22 Lambourne Retreat, Mirrabooka

WA 6061 Australia

T: +61 (0) 400 825 345

| Send email now to: | head(at)allmineral.com |

| Call now: | +49 (0) 211 522 88 0 |