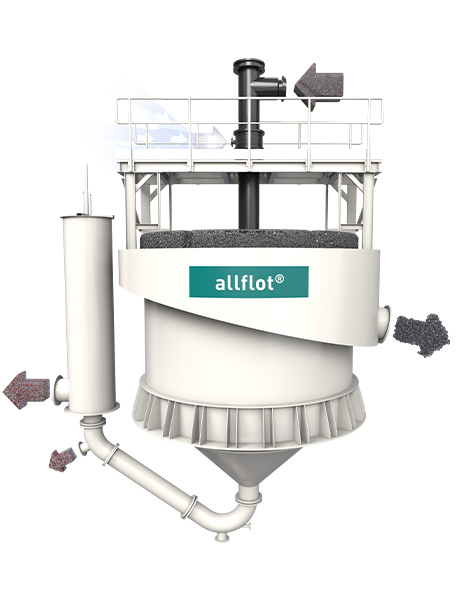

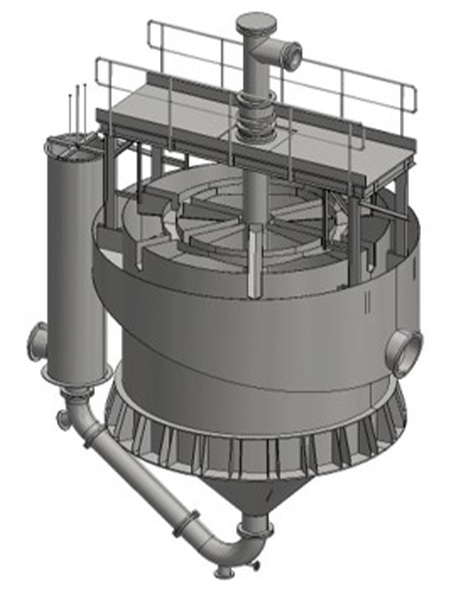

The unique allflot® machine increases both the yield and quality of minerals. It features an innovative new ventilation concept crafted by our engineers and offers the maximum possible flexibility in terms of the volumetric throughput rate.

- Highly efficient and flexible use of flotation technology for high-quality mineral enrichment

- Energy-efficient, space-saving solution

- Adjustable air bubble size and volume for improved product purity and increased mineral yield

- Long-lasting investment thanks to ceramic nozzles with a service life of over 10,000 hours for mineral enrichment and over 40,000 hours for coal processing

More individual consulting

tailored to your needs.

Get in touch and talk to our experts.

We’re happy to help: contact us here.