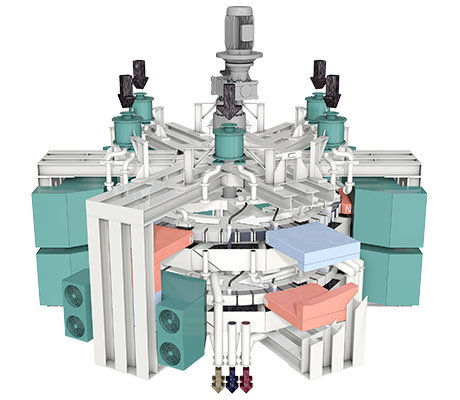

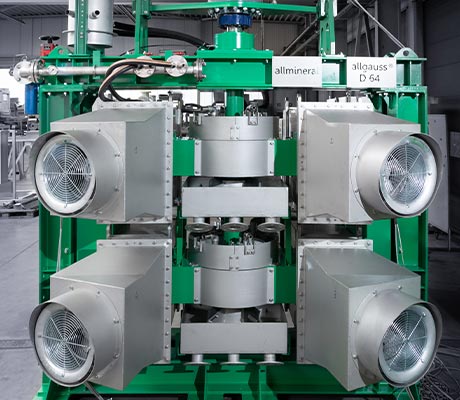

High-precision separation, excellent flexibility and energy efficiency.

The allgauss® is a straightforward, flexible and robust solution that delivers optimum results.

- Cutting-edge technology and innovative control enable a wide variety of applications such as rougher, cleaner and 2-stage separation in an allgauss®

- Throughput of up to 1,400 t/h in one machine

- magnetic field strength of up to 15,000 gauss

- Saves energy thanks to specially developed magnet system

More individual consulting

tailored to your needs.

Get in touch and talk to our experts.

We’re happy to help: contact us here.