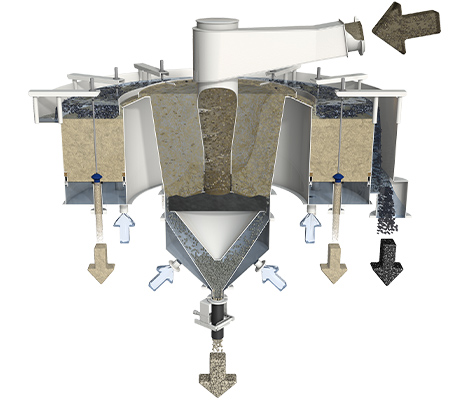

The allflux® procedure uses fluidised bed technology for density sorting and hydraulic classification. This two-stage treatment makes it possible to process a mixture of sand and water without pre-thickening. An upflow that passes through the feed slurry at the coarse sand level causes the light and fine particles to rise up, with the sinking coarse and heavy particles being removed.

The fine sand level, a circular process that constitutes the second stage, is reached by the light material – including the fine particles that form an autogenous fluidised bed. The light material awaiting separation floats on this bed and subsequently spills over with the upflow of water.

- Sorting, classification, thickening and cleaning all performed in a single unit

- Production of quality sand from deposits featuring impurities

- Consistent material quality via automatic process control

- Low energy requirement and low wear

More individual consulting

tailored to your needs.

Get in touch and talk to our experts.

We’re happy to help: contact us here.