Second coal preparation plant for Indonesien

allmineral delivers second coal preparation plant in Indonesia. Innovative raw material processing with state-of-the-art mining equipment. Find out more now!

Initial situation in the Indonesian coal sector

Indonesia is one of the world's most important coal-producing regions for raw material processing. Especially where dense jungle areas and remote locations make infrastructure difficult, operators face particular challenges: increasing demand for energy and raw materials, increasingly scarce land and pressure to make processes more efficient and sustainable.

For one of allmineral's long-standing partners, it was clear that the existing capacity was no longer sufficient to meet the growing demand. At the same time, operational reliability could not be allowed to suffer - on the contrary, it needed to be safeguarded in the long term with state-of-the-art technology.

This is exactly where allmineral comes in. With the planning and delivery of a second coal preparation plant, the company is once again proving that it not only supplies machines, but also complete solutions for the raw materials industry. Precise engineering, well thought-out project implementation and the use of state-of-the-art mining equipment ensure that maximum performance is achieved even under demanding conditions.

Read this article to find out how allmineral laid the foundations for the customer's expansion with innovative technologies for processing mineral raw materials - and the measurable benefits that have resulted.

allmineral doubles production capacity with new coal processing plant

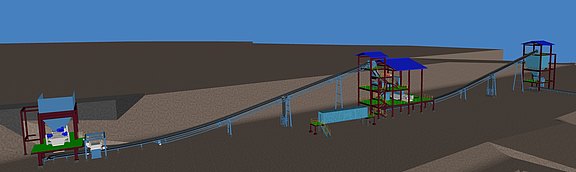

The Indonesian customer is pursuing an ambitious expansion strategy: existing coal production is to be doubled with the construction of a second processing plant. This will significantly increase the overall capacity - a decisive step towards meeting the growing demand for energy and raw materials in the region.

The challenge here is that there is only a limited amount of space available at the site, which nevertheless has to accommodate a high-performance plant with state-of-the-art raw material processing. At the same time, the customer expected maximum reliability, short project lead times and the integration of state-of-the-art mining equipment.

Technical solution and mining equipment

In order to realize the ambitious doubling of the coal preparation capacity, allmineral relied on a tailor-made plant concept with state-of-the-art mining equipment and proven preparation technology.

Core components and technologies for coal preparation

- HAZEMAG Feeder Breaker and Mineral Sizer for efficient crushing

- 500tph custom designed dense medium plant for precise separation of coal and rock

Key technical data

- Throughput capacity: 500 tons per hour

- Plant design: adapted to limited footprint on site

- Scope of services: Delivery, project management, performance guarantees

Result and added value for the customer

The plant is an integral part of the customer's expansion strategy. The complete solution delivered by allmineral provides the following benefits:

- double the coal preparation capacity from 500 TPH to 1,000 TPH,

- improve product quality - through more precise separation of coal and secondary rock in the custom designed dense medium plant

- reduced operating costs – thanks to energy-efficient crushing and optimized process flow

- ensure long-term operational reliability - supported by dedicated site service team and SLA

Would you like to increase your capacities and benefit from our engineering expertise?

Request a consultation now.

Aftersales and sites services for raw material processing

The partnership does not end with commissioning. allmineral supports the customer with

- Spare parts supply

- maintenance and services

- complete life cycle management of the plant

This guarantees planning reliability, high availability and long-term efficiency.

Conclusion - efficiency through technology and partnership

With its second coal preparation plant in Indonesia, allmineral is once again proving its role as a leading partner in raw material preparation.

Contact us, to plan your next expansion.

Find out more about our solutions for processing mineral raw materials.

Technical data (short profile):

- 500 TPH DMS Plant

- HAZEMAG Feeder Breaker

- Mineral Sizer

- compact design for limited footprint

FAQ on coal preparation, DMS technology and services

A DMS plant (Dense Medium Separation) enables precise separation of coal from waste rock. This leads to higher yield and a final high-grade coal product.

From spare parts, technical support and site services, allmineral ensures smooth operation during the complete life cycle.

Yes, the current project in Indonesia shows that allmineral can deliver efficient solutions even where space is limited.

Internal links at a glance

- Product overview Our products

- Spare parts service Maintenance & repair

- Service profile Services

- O&M services Production support

- Dry Processing allair® dry processing

- Contact Contact page

- Hazemag Feeder Breaker Horizontal crushers

- Hazemag Mineral Sizer Sizer

| Send email now to: | head(at)allmineral.com |

| Call now: | +49 (0) 211 522 88 0 |