Efficient Coal Processing with a modular Plant in Indonesia

How Operations & Maintenance by allmineral Increased Plant Availability by 4%.

How Operations & Maintenance by allmineral Increased Plant Availability by 4%

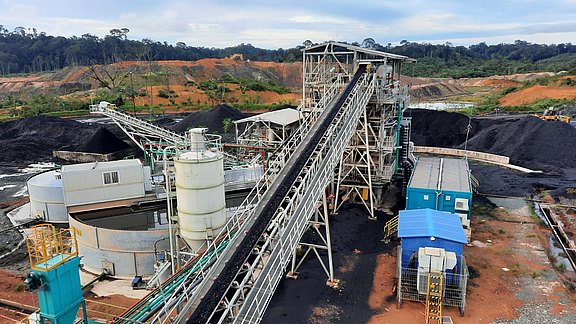

Deep in the Indonesian jungle on Borneo, far from any urban infrastructure, a semi-modular coal processing plant is delivering impressive results. The key success factors? Reliability, recovery, and adaptability. These are precisely what allmineral provides — through a comprehensive Operations & Maintenance (O&M) concept designed to ensure maximum efficiency.

Semi-modular Coal Processing Plant in Operation for PT Asmin Bara Bronang

PT Asmin Bara Bronang (ABB) required a flexible and robust solution for upgrading raw coal — one that could be deployed and maintained in remote mining regions.

The solution:

- Semi-modular processing plant designed, built, and commissioned by allmineral

- Capacity: 125 tons per hour

- Feed material: -300 mm raw coal

- Final product: -50 mm washed coal

- Core technology: alljig® GR 1700 for density separation

This modular processing plant is ideal for remote or temporary operations — compact, powerful, and highly productive.

How O&M Services Help Increase Plant Availability

All-in-One Operations & Maintenance Approach

allmineral not only delivered the plant, but continues to operate, monitor and maintain it through a dedicated on-site team — part of its full-service O&M (Operations & Maintenance) offering.

Key services:

- Continuous KPI monitoring and optimization

- Planned shutdown support and troubleshooting

- Spare parts forecasting and delivery

- Training and skills transfer for ABB’s local team

- Remote plant monitoring via allconnect®

Want to know more about our O&M Services? Visit: allmineral.com/en/services

Proven Results – In Hard Numbers

| KPI | Target | Achieved |

|---|---|---|

| Yield | 75 % | +4 % above |

| Ash content (final) | < 8,1 % | consistently < 8 % |

| Plant availability | Previous year | +4 % increase |

Curious how your plant could benefit? Contact us today!

Technology in Use – alljig® , HFB & More

The plant combines world-class technologies:

- HFB 0714 Crusher: Reduces raw coal to -50 mm

- alljig® GR 1700: Density-based classification of +1 to 50 mm particles

- Online ash analyzer: Continuous product quality control

- Hydrocyclones, spirals, belt filter press: Efficient tailings handling

Learn more about our coal processing technologies

Why allmineral is Your Ideal O&M Partner

From Engineering to Operation – Everything from One Source

We offer full support across all project phases:

- Plant design & engineering

- Delivery & commissioning

- Ongoing operation & process optimization

- Spare parts logistics & maintenance

- Technical audits and onsite support

Explore our full-service O&M portfolio

Sustainable and Future-Proof Solutions

- Water-saving dry processing via allair® technology

- In-house Global Testing & Research Center for continuous innovation

- Contribution to ESG goals: energy efficiency, emissions reduction, and smarter resource usage

Learn more about allair® dry processing

Conclusion – Rethinking Coal Processing

This project in Indonesia proves how powerful the right combination of plant design, modern service and data-driven optimization can be.

- A modular processing plant tailored to field conditions

- A dedicated O&M team improving operations daily

- Measurable improvements in recovery, quality and uptime

→ Ready to increase your plant availability?

FAQ – for Engineers, Managers and Project Owners

→ O&M stands for Operations & Maintenance. An external partner like allmineral operates, monitors, and maintains your plant to ensure maximum uptime and product quality.

→ Flexibility, compact design, fast deployment, and suitability for remote or changing mining sites.

→ Through preventive maintenance, real-time performance monitoring, responsive spare part logistics, and continuous process optimization.

Still have questions? Get in touch with our team

Internal Links at a Glance

- Product technology (e.g. alljig®) alljig® product page

- Full product overview Products Overview

- Spare parts and maintenance Spare Parts & Maintenance

- Full service offering (O&M) O&M Services

- Dry processing technologies allair® Dry Processing

- Contact page Contact us

| Send email now to: | head(at)allmineral.com |

| Call now: | +49 (0) 211 522 88 0 |